No products in the cart.

How to convert engines to use hydrogen as primary fuel

Hydrogen enhances combustion of the existing fuel which results in significant economy gains due to the fact that hydrogen-fuel mixtures burns more completely.

However, the challenges to produce enough hydrogen to run an engine without gasoline include:

- an excessively large and expensive HHO generating system

- the battery of the vehicle is not capable of providing the necessary current

- the HHO generator, water reservoir and battery bank would fill a trailer that must be towed by the car

- impossible to control the HHO flow to meet the dynamic needs of a gasoline engine

To illustrate, here are calculations for a very small, 1 liter engine conversion to run 100% on hydrogen HHO

This engine is rated at 50 HP, 37 KiloWatts

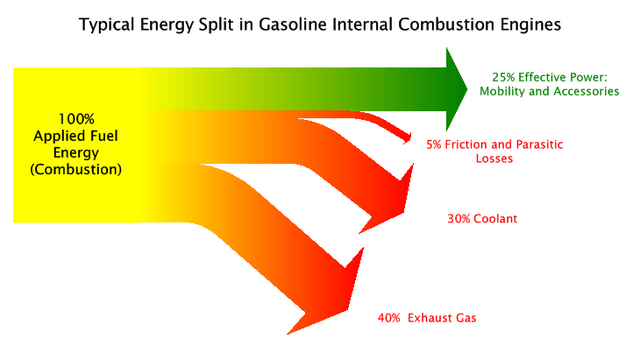

Losses occur every time energy is converted from one form to another.

Internal combustion engines convert gasoline to mechanical energy at 25% efficiency.

As a result, the engine requires 148 KW of input energy rate (HHO) to produce an output power of 37 KW.

Consumer grade electrolysers are about 50% efficient, thus 296 KW of electrical power is required to produce the necessary 148 KW of HHO. This power is taken from the battery of the car.

12 Volt batteries must supply 25,000 Amps to achieve 296 KW.

Automotive batteries can deliver 25 Amps for an extended time and are rated for 1.5 hours. In this example, even if 1000 batteries are used, the vehicle can only drive for 1.5 hours.

In addition to the impractical battery bank and a generator capable of producing 1562 liters per minute of HHO, the engineering challenge of this project is virtually impossible.

Vehicle engines are very dynamic in their fuelling requirements and change dramatically within fractions of a second.

Electrolysis, by nature is unresponsive, meaning you cannot quickly change the hydrogen flow rate up or down.

There is no possible way to control 25000 amps and manipulate the HHO flow accurately to meet the dynamic needs of a gasoline engine to make the engine operate correctly.

In conclusion, if a 296 KW battery source is available, it would be much more efficient to use it in an electric vehicle and avoid all the energy losses of the gasoline engine and the electrolyser.

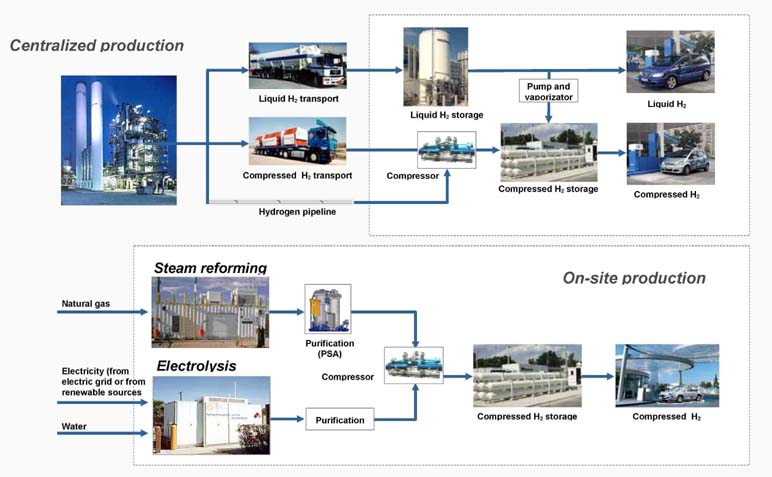

hydrogen refueling station components

Read more:

How hydrogen generators for vehicles work

How to select correct equipment

Setup and operation of HHO equipment, safety, compatibility

How to calculate maximum Hydrogen output

What happens when too much hydrogen is supplied to an engine

Results of NASA’ s experiments with hydrogen in internal combustion engines

Visit our store

Summary

Article Name

How to convert engines to operate exclusively, 100% on hydrogen

Description

Hydrogen enhances combustion of the existing fuel which results in significant economy gains due to the fact that hydrogen-fuel mixtures burns more completely.

The challenges to produce enough hydrogen to run an engine without gasoline include:

-an excessively large and expensive HHO generating system

-the battery of the vehicle is not capable of providing the necessary current

-the HHO generator, water reservoir and battery bank would fill a trailer that must be towed by the car

-impossible to control the HHO flow to meet the dynamic needs of a gasoline engine

Author

Better Fuel Technology

Publisher Name

Better Fuel Technology

Publisher Logo